- What Is Biochar?

Biochar is a carbon-rich, charcoal-like substance derived from the controlled pyrolysis (heating in limited oxygen) of organic biomass such as crop residues, wood chips, or farm waste. Unlike regular charcoal, biochar is produced specifically for enhancing soil health and for its ability to sequester carbon for hundreds, potentially thousands, of years.

The transformation of waste biomass into biochar doesn’t just lock away carbon. It also yields a stable material with a porous structure ideal for improving soil water retention, nutrient capacity, and microbial habitats. As an agricultural tool, biochar holds tremendous promise for sustainable farming and climate resilience.

- Importance of Biochar in Natural Farming Practices

Biochar is a natural fit for organic and natural farming systems that seek to avoid synthetic inputs and focus on ecological balance. Its roles in supporting soil health and sustainable agriculture include:

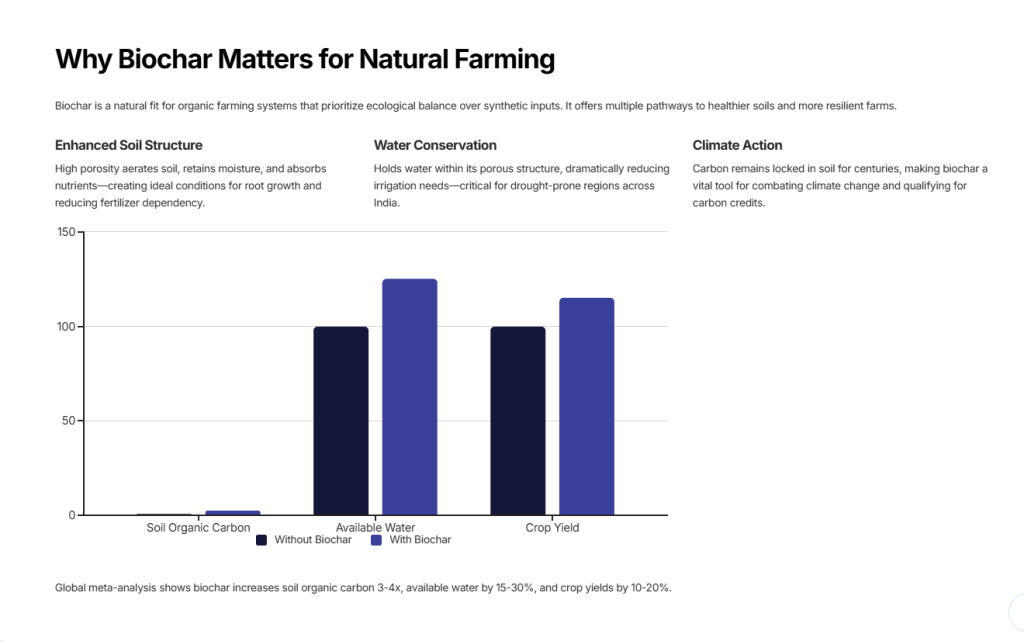

Soil Structure and Fertility: Biochar’s high porosity helps aerate the soil, retains moisture, and absorbs nutrients. This creates the ideal environment for root growth and beneficial soil microbes, reducing dependency on fertilizers.

Water Conservation: By holding water within its porous structure, biochar dramatically reduces irrigation needs—critical for drought-prone areas.

Carbon Sequestration: The carbon in biochar remains locked in the soil for centuries, making it a vital tool in combating climate change and qualifying for carbon credits.

Erosion Control & Pollution Reduction: Biochar stabilizes soil, curbing erosion and runoff, and can adsorb toxins from water and soil, further benefitting the ecosystem.

Biochar’s Impact on Soil and Yield (Global Meta-Analysis)

Parameter Without Biochar With Biochar Improvement

Soil Organic Carbon ~0.7% >2.5% 3-4x higher

Available Water Baseline +15–30% +15–30%

Crop Yield Baseline +10–20% +10–20%

3. How Biochar Benefits Match with the Vision and Mission of Gratitude Farms

At Gratitude Farms, the mission is to transform barren and unused land into fertile, carbon-rich, and microbially active ecosystems using ancient Indian wisdom blended with smart, sustainable innovation. Biochar is a cornerstone of this transformation:

- Regenerative Farming: Biochar revives degraded soils, aligning with the vision of turning wastelands productive using eco-friendly inputs.

- Water Conservation: Water management—vital in Gratitude Farms’ development—finds a powerful ally in biochar, which improves water use efficiency and strengthens resilience to drought.

- Climate Responsibility and Community: By sequestering carbon and using local farm residues, biochar reflects values of environmental stewardship and community empowerment.

- Holistic Ecosystems: The farm’s use of ancient Vriksh Ayurveda and Nakshatra Vanam traditions is deepened through biochar, which supports plant health and biodiversity from root microbe to canopy.

4. Process of Making BEC (Biochar Enhanced Compost) from Biochar

BEC, or Biochar Enhanced Compost, is a synergistic blend of biochar and organic compost that maximizes soil benefits.

Steps for Making BEC

Step Description

1. Biochar Preparation Pulverize biochar to less than 1–2 cm size for uniform mixing.

2. Composting Setup Use standard windrow, bin, or pile compost methods with

desired feedstock.

3. Mixing Ratio Add biochar at 5–20% by volume to composting material.

4. Layering Alternate layers of compost (farm waste, manure) and

biochar.

5. Moisture Control Maintain ~60% moisture using the squeeze test.

6. Regular Turning Turn pile weekly to aerate and ensure even decomposition.

7. Maturation Compost for 2–3 months until fully decomposed and

temperature stabilizes.

The presence of biochar accelerates composting, absorbs odors, improves microbe activity, and binds nutrients to reduce losses from leaching or volatilization.

5. Pyrolysis Process for Making Biochar in Bulk

Bulk biochar production uses pyrolysis, which involves heating biomass in a low-oxygen environment to break it down into biochar, syngas, and wood vinegar.

Bulk Pyrolysis Process – Stages Overview

Stage Description Typical Temp

Drying Removes moisture from biomass. 100–200°C

Pre-carbonization Starts decomposition; releases some gases. 200-300°C

Carbonization/Pyrolysis Main breakdown; produces most biochar 350-600°C

and volatile compounds.

Calcination Further cracks volatiles; raises fixed carbon content. 600°C+

- Feedstock: Can be crop waste, wood chips, sugarcane bagasse, or husk.

- Equipment: Simple earth kilns for small farms, or rotary kilns/retorts for commercial scale.

- Outputs: Biochar (solid), wood vinegar and tar (liquid), and syngas (gas, sometimes used as a heat source for the kiln itself).

6. Conclusion: Gratitude Farms and Large-Scale Impact

Gratitude Farms stands at the confluence of ancient Indian practice and modern regenerative agriculture. By adopting and promoting biochar and BEC across its projects, Gratitude Farms:

- Transforms Degraded Land: Rapidly increases organic carbon, boosts microbial activity, and reverses soil decline.

- Promotes Water Security: Enhances soil water retention and reduces irrigation costs—key for India’s future food security.

- Supports Farmers & Community: Demonstrates replicable, modular farming models to smallholder groups, women’s self-help collectives, and marginal agriculturists.

- Leads in Climate Solutions: By sequestering atmospheric carbon at scale, the farm participates directly in the mission of net-zero rural India, opening opportunities for carbon credits and eco-certification markets.

- Drives Awareness and Training: Empowers farmers with training and practical exposure, ensuring the biochar revolution spreads far and wide.

Gratitude Farms, through the adoption of biochar and BEC, is not just growing crops—it is cultivating healthy soils, resilient communities, and a sustainable, climate-positive future for Indian agriculture.